Zero Waste Production: How Robotics Reduce Scrap Rates by 80% | CNN Robotics

Our insights on how robotics slash scrap rates by up to 80% in manufacturing & Learnings on how precision automation reduces waste, boosts ROI, and drives sustainable, zero-waste production.

Waste: The Silent Profit Killer

Every factory leader knows downtime. When machines stop, production lines stall, and losses are visible on the balance sheet. But waste? Waste is quieter – and in many cases, far more dangerous.

Scrap parts, rework, and material inefficiencies don’t flash alarms, yet they silently drain profitability every single day. In high-volume production, even a small scrap rate can translate into thousands of defective units a week. That’s raw material wasted, operator effort misused, and energy consumed for no value delivered.

For modern factories, the key question has shifted. It is no longer simply:

“How fast can we run?”

It is:

“How little can we waste?”

The Hidden Cost of Scrap

Scrap is more than a quality issue. It creates ripple effects that touch finance, operations, sustainability, and even reputation.

- Financial Costs: Each defective part consumes raw material, energy, and labor that can never be recovered. Even a 2-3% scrap rate can erase millions in annual margin for large-volume manufacturers.

- Operational Inefficiency: Rework slows the entire line. Scrap doesn’t just affect the defective part – it eats into capacity, clogs workflows, and diverts skilled operators away from value-adding tasks.

- Environmental Impact: Scrap undermines sustainability targets, increases carbon emissions, and complicates ESG reporting. Every wasted part is wasted energy and wasted resources.

- Reputational Risk: Persistent scrap rates erode customer trust. In sectors like automotive, aerospace, and pharma, defective products can damage relationships and delay approvals for future contracts.

Scrap is, in short, a triple threat: financial, operational, and reputational.

Why Scrap Happens

Scrap often isn’t caused by one catastrophic issue – it’s the accumulation of small inefficiencies.

- Inconsistent manual processes leading to variable quality.

- Machine wear going undetected until entire batches are compromised.

- Parameters not optimized, resulting in over-welding, over-cutting, or material excess.

- Human error in inspection, letting defects slip further down the line.

These issues may seem minor in isolation, but in a high-volume setting, they compound quickly. This is where robotics steps in to shift the equation.

How Robotics Reduce Scrap by Up to 80%

Factories implementing robotics have reported scrap reductions in the range of 60-80%, not because robots are “perfect,” but because they combine repeatability, monitoring, and optimization in a way that manual processes simply cannot.

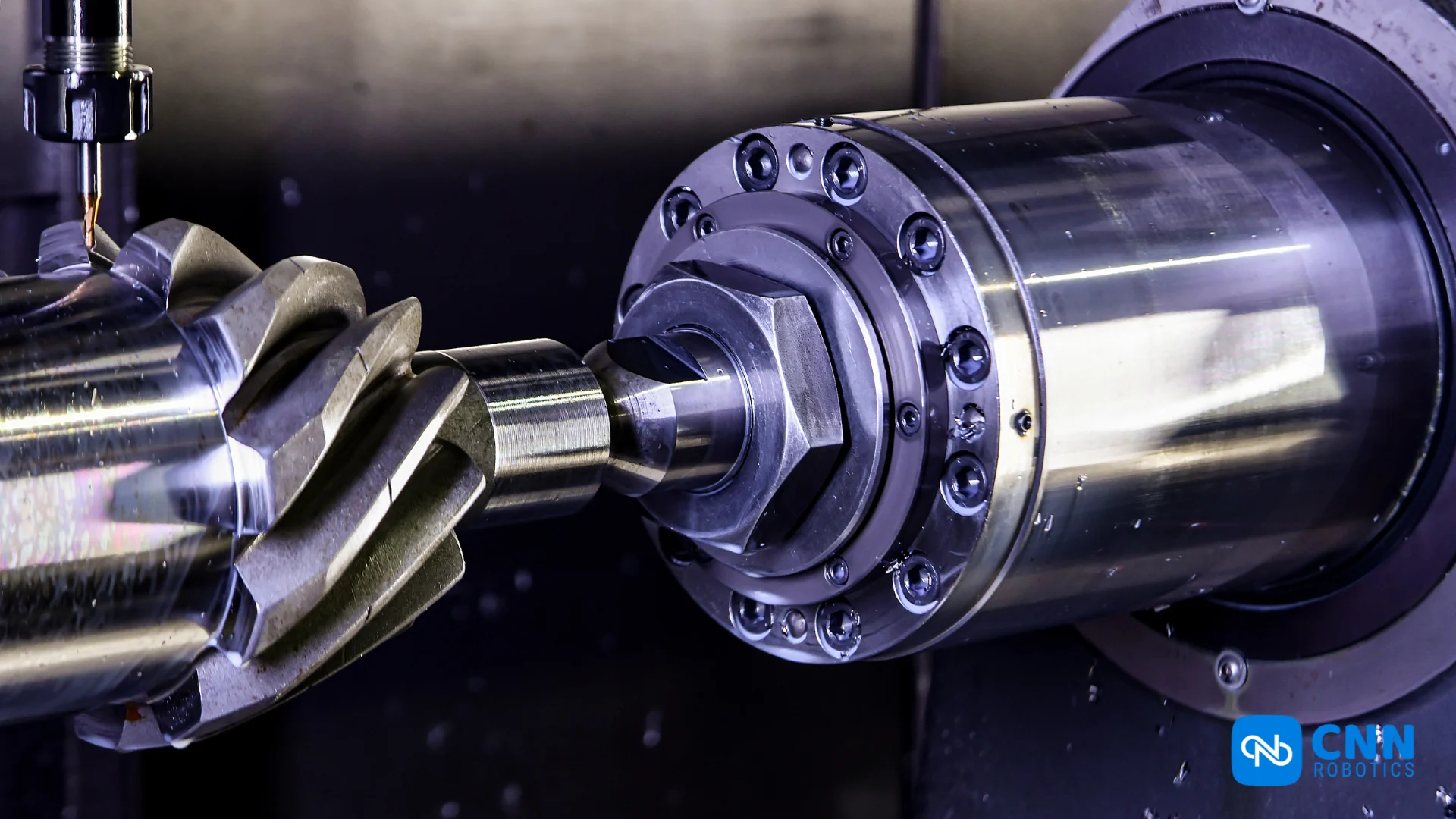

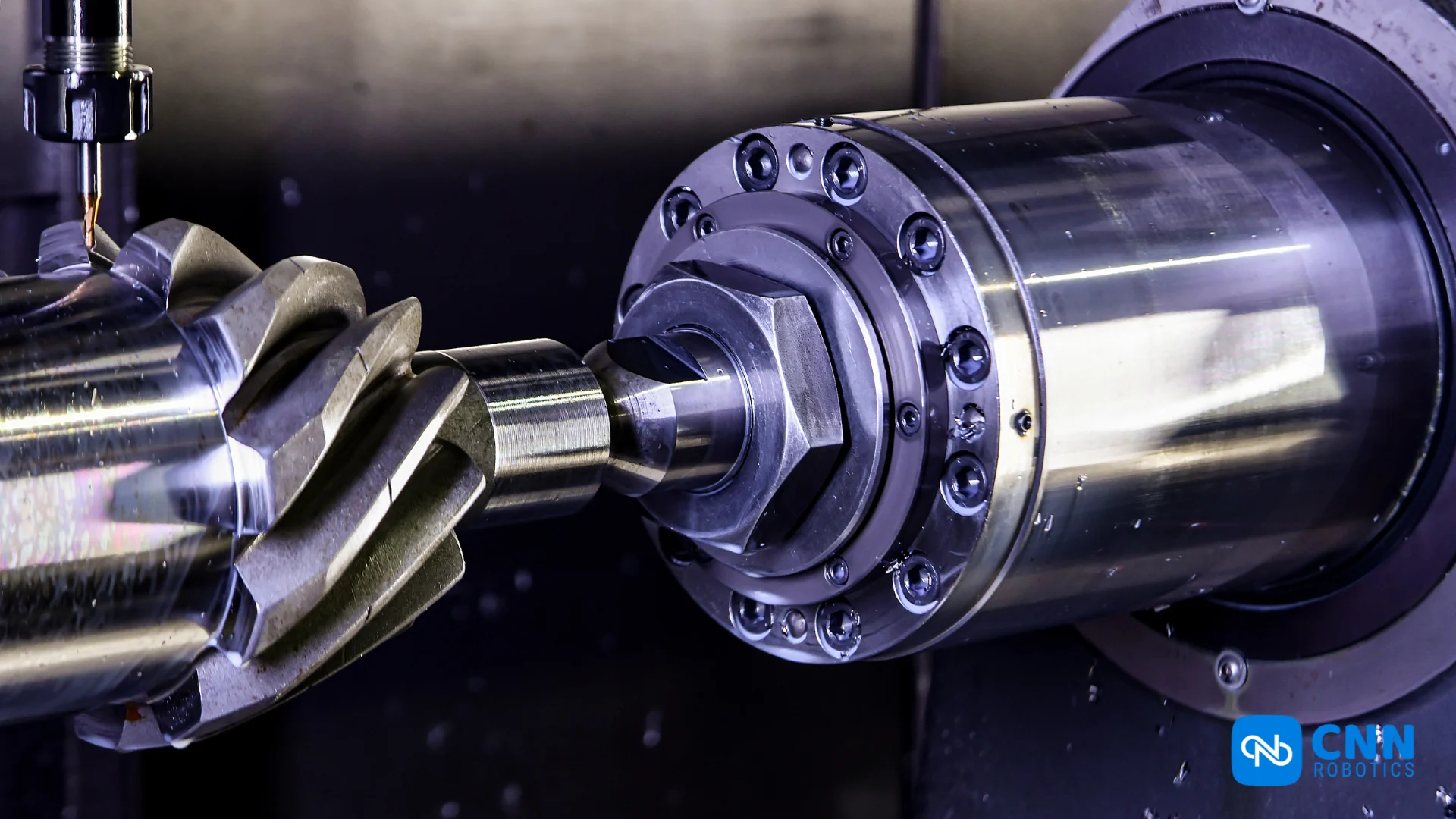

1. Precision Engineering

Robots execute the same operation with micrometer accuracy, thousands of times in a row. Unlike manual operators, they don’t fatigue, lose focus, or vary between shifts. A consistent weld, cut, or placement means fewer errors and tighter quality control.

2. Real-Time Monitoring

Modern robotic systems integrate seam tracking, vision systems, and advanced sensors. These don’t just flag issues – they correct them in real time, ensuring one small defect doesn’t multiply into hundreds of faulty units.

3. Optimized Programming

With robotics, process paths and parameters can be refined for minimal waste. Whether it’s optimizing welding bead size or fine-tuning cutting paths, robots ensure material is used exactly as needed – no more, no less.

4. Automated In-Line Checks

Instead of relying on end-of-line inspection, robots integrate checks into the production process itself. Defects are flagged and rejected instantly, reducing large-scale rework and protecting downstream efficiency.

Together, these capabilities create a closed loop of prevention, correction, and optimization. Scrap never gets the chance to snowball.

Industry-Specific Impact

Automotive & Aerospace

In these sectors, even the smallest deviation can compromise safety. Robotic welding, fastening, and inspection cut defects dramatically while ensuring regulatory compliance. Scrap reduction here isn’t just financial — it’s about protecting brand reputation and safety standards.

Food & Pharmaceutical Packaging

In these sectors, even the smallest deviation can compromise safety. Robotic welding, fastening, and inspection cut defects dramatically while ensuring regulatory compliance. Scrap reduction here isn’t just financial — it’s about protecting brand reputation and safety standards.Scrap packaging is a double loss: wasted material and wasted product inside. Robotics ensures consistent sealing, labeling, and serialization, keeping defect rates low and compliance intact.

FMCG & Consumer Goods

High-volume production means that even a small defect rate can balloon into massive waste. Robotics delivers the consistency needed to keep lines running at scale with near-zero errors.

Energy & Heavy Fabrication

Large parts and assemblies are expensive. Scrap here can cost tens of thousands of dollars per unit. Robotic systems reduce errors during welding and machining, protecting both costs and safety.

The Payback Beyond Savings

High-throughput robotics are not just about hitting production numbers. They reshape cost structures and business outcomes:Reducing scrap is not just about cutting costs – though the financial impact is immediate and measurable. The ripple effects extend across the factory and the business.

- Material Efficiency: Lower scrap translates directly into lower raw material spend, freeing up working capital.

- Operational Flow: Fewer defects mean less rework, smoother line balance, and more predictable delivery schedules.

- Sustainability Gains: Reducing waste lowers energy consumption and carbon footprint – strengthening ESG positioning and compliance.

- Employee Productivity: Operators spend less time correcting defects and more time focused on value-adding tasks or innovation

- Customer Confidence: Consistently high-quality output reduces complaints, strengthens long-term contracts, and positions manufacturers as reliable partners.

Zero Waste as a Competitive Strategy

As markets tighten and sustainability pressures grow, zero waste is no longer just an ideal – it’s a necessity. Manufacturers that treat waste reduction as a strategic priority gain:

- Higher margins through material and energy savings.

- Stronger ESG credentials in markets where sustainability is becoming a differentiator.

- Greater resilience, with fewer inefficiencies slowing growth.

This isn’t about chasing perfection. It’s about ensuring that every unit produced delivers value, not loss.

In manufacturing, speed often takes the spotlight. But the factories that will lead tomorrow are those that combine volume with precision, and speed with sustainability.

By adopting robotics and precision automation, manufacturers are proving they can cut scrap rates by up to 80%, strengthen profitability, and achieve their sustainability goals — all at once.

At CNN Robotics, we see this shift happening every day with our partners across industries. And it’s only the beginning.

👉 To explore more insights like this, follow CNN Robotics on LinkedIn and join the conversation on how automation is reshaping modern factories.